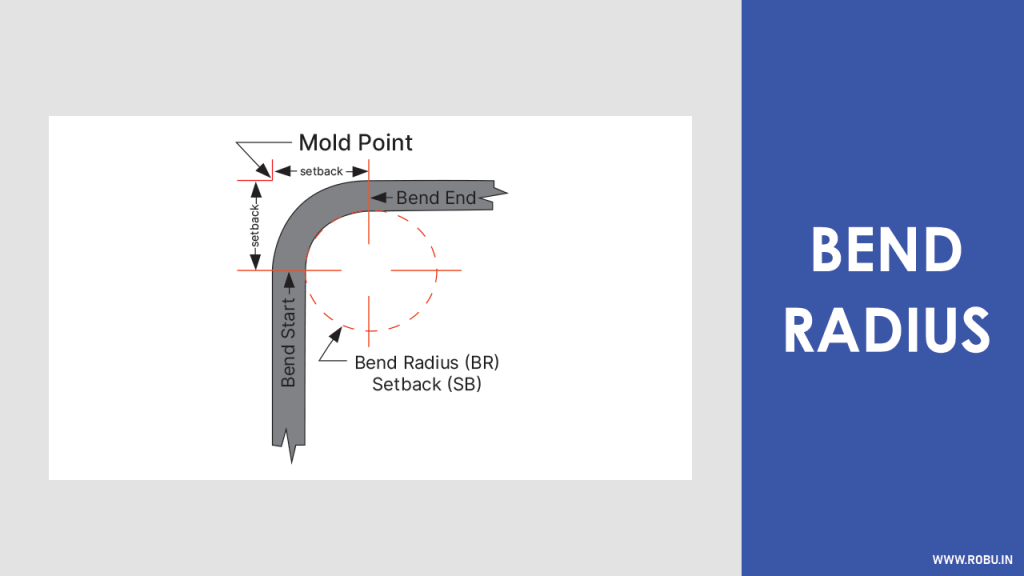

Bend Radius Sheet Metal - When designing sheet metal parts, understanding the minimum bend radius is crucial to ensuring the structural integrity and functionality of the final product. The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. The bend radius is the inside radius of a bent sheet metal part and has a direct impact on the part’s structural integrity, its ability to withstand stresses, and its final quality. Your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs. This radius is dependent on the material. How to implement the industry standard sheet metal bend radius. The minimum bend radius is the.

The minimum bend radius is the. Your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs. The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. When designing sheet metal parts, understanding the minimum bend radius is crucial to ensuring the structural integrity and functionality of the final product. The bend radius is the inside radius of a bent sheet metal part and has a direct impact on the part’s structural integrity, its ability to withstand stresses, and its final quality. This radius is dependent on the material. How to implement the industry standard sheet metal bend radius.

Your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. When designing sheet metal parts, understanding the minimum bend radius is crucial to ensuring the structural integrity and functionality of the final product. The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. The minimum bend radius is the. How to implement the industry standard sheet metal bend radius. This radius is dependent on the material. The bend radius is the inside radius of a bent sheet metal part and has a direct impact on the part’s structural integrity, its ability to withstand stresses, and its final quality. Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs.

Sheet Metal Bend Radius Calculator at Horace Winfield blog

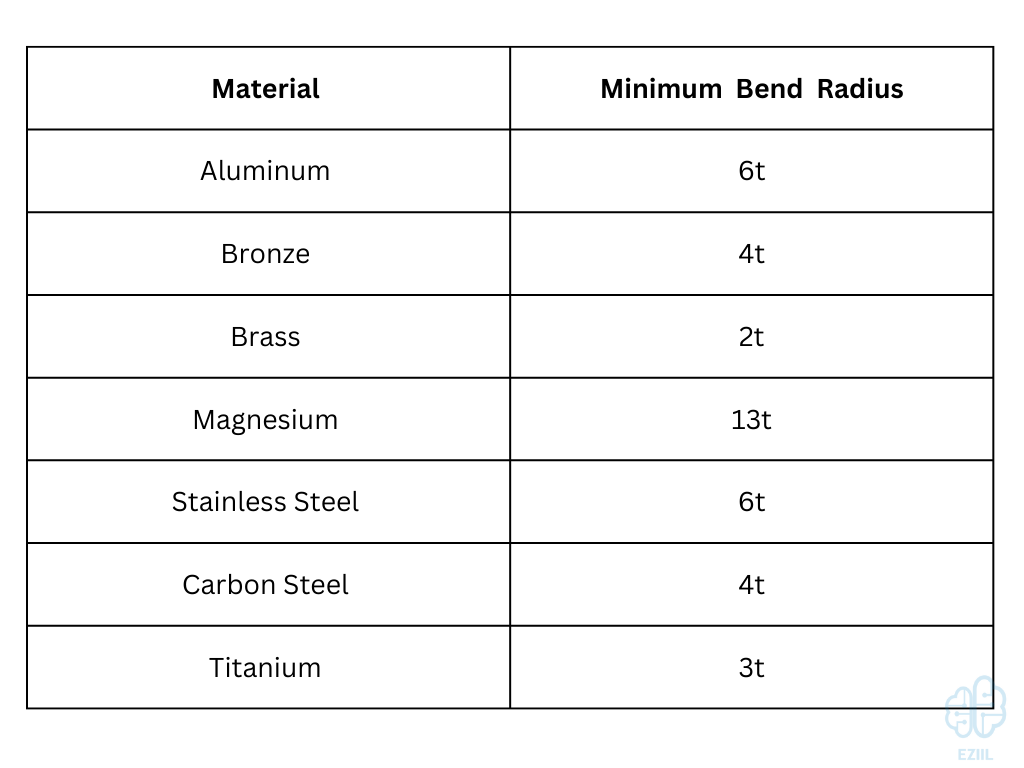

This radius is dependent on the material. When designing sheet metal parts, understanding the minimum bend radius is crucial to ensuring the structural integrity and functionality of the final product. Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs. The bend radius is the inside radius of a bent sheet metal.

Kfactor Calculator for Sheet Metal Bending SMLease Design

The bend radius is the inside radius of a bent sheet metal part and has a direct impact on the part’s structural integrity, its ability to withstand stresses, and its final quality. The minimum bend radius is the. How to implement the industry standard sheet metal bend radius. Your best bet when designing formed parts is to use the industry.

Sheet Metal Bend Radius Full Guide Chart

Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs. This radius is dependent on the material. The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. The minimum bend radius is the. How to implement the industry standard.

Sheet Metal Bend Radius Calculator at Horace Winfield blog

Your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. The minimum bend radius is the. Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs. How to implement the industry standard sheet metal bend radius. When designing sheet metal parts, understanding the minimum bend.

Sheet Metal Bending Calculation With Example at Rita Skelley blog

How to implement the industry standard sheet metal bend radius. The bend radius is the inside radius of a bent sheet metal part and has a direct impact on the part’s structural integrity, its ability to withstand stresses, and its final quality. The minimum bend radius is the. This radius is dependent on the material. When designing sheet metal parts,.

Sheet Metal Design Basics in 2021 Complete List of Things

The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. When designing sheet metal parts, understanding the minimum bend radius is crucial to ensuring the structural integrity and functionality of the final product. The minimum bend radius is the. This radius is dependent on the material. The.

Minimum Bend Radius Reference Table For Sheet Metal Xometry Pro

This radius is dependent on the material. The bend radius is the inside radius of a bent sheet metal part and has a direct impact on the part’s structural integrity, its ability to withstand stresses, and its final quality. Your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. The minimum bend radius.

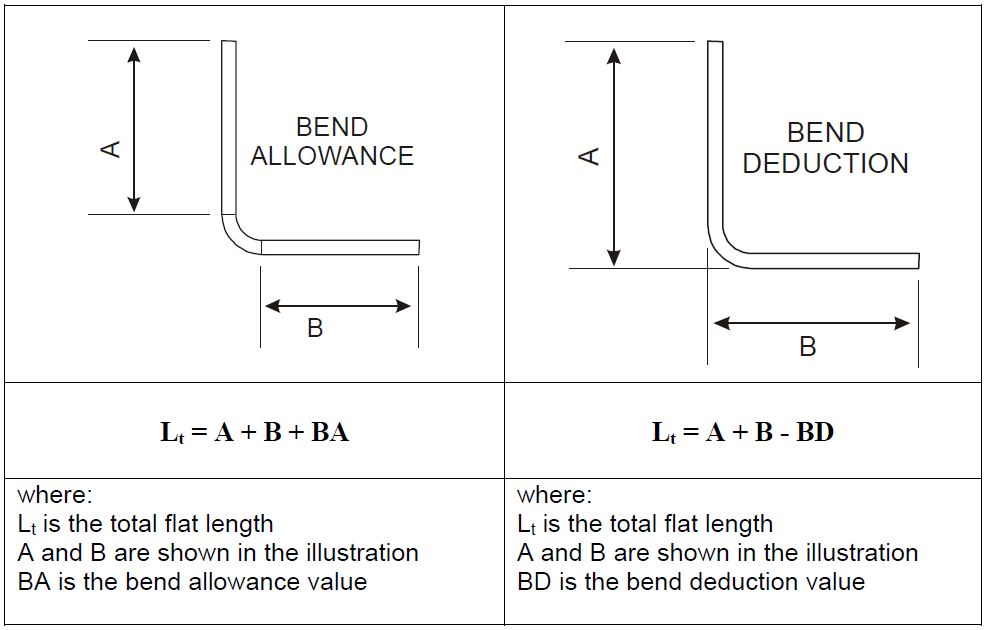

Learn Sheet Metal Design Terminology including Bend Deduction

When designing sheet metal parts, understanding the minimum bend radius is crucial to ensuring the structural integrity and functionality of the final product. Your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. The minimum bend radius is the. The sheet metal bending radius is a critical value in sheet metal drawing that.

Sheet Metal Bend Radius Guidelines

The minimum bend radius is the. The bend radius is the inside radius of a bent sheet metal part and has a direct impact on the part’s structural integrity, its ability to withstand stresses, and its final quality. How to implement the industry standard sheet metal bend radius. When designing sheet metal parts, understanding the minimum bend radius is crucial.

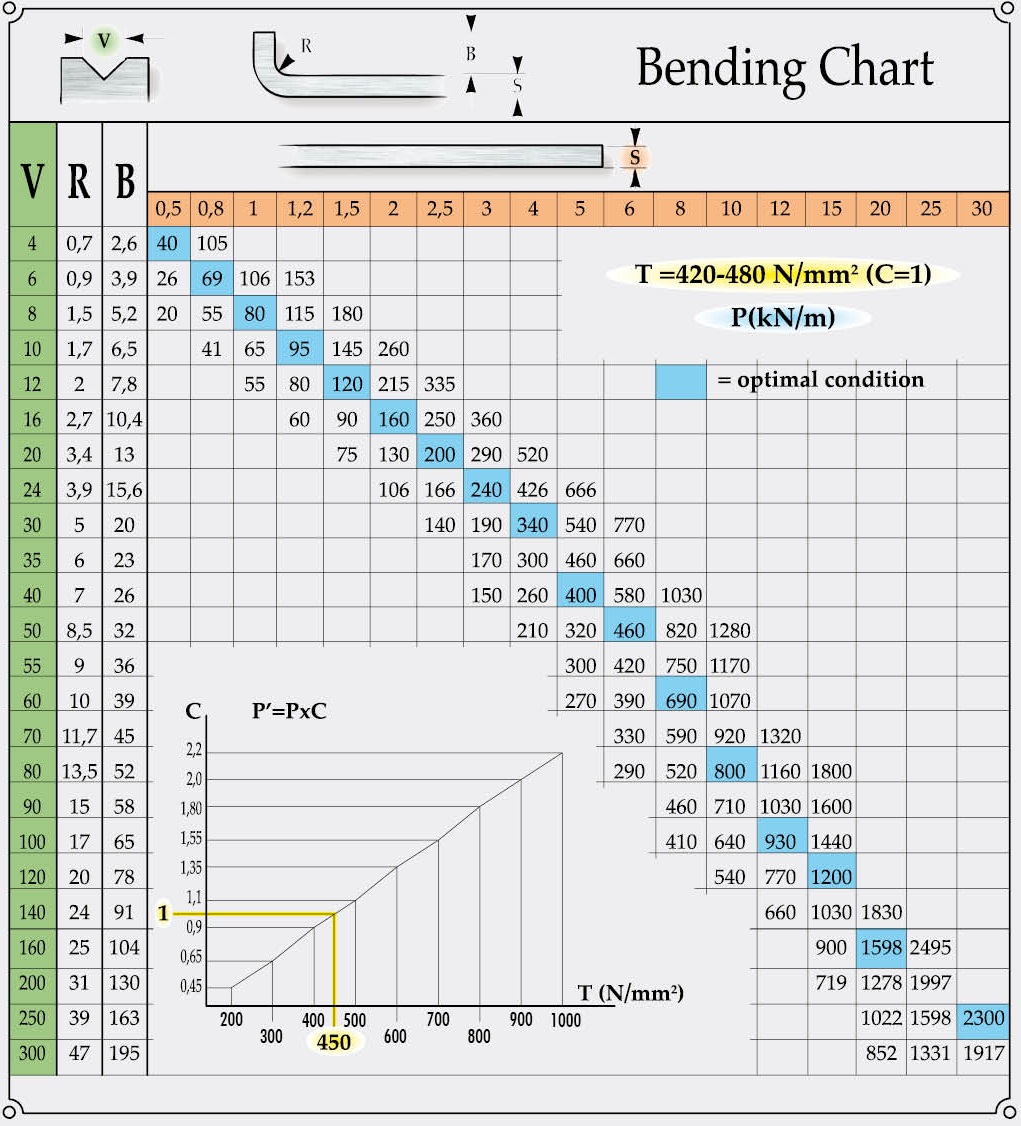

The metal sheet bending table are the basis of the operation of the metal

The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs. When designing sheet metal parts, understanding the minimum bend radius is crucial to ensuring the structural integrity and functionality.

The Minimum Bend Radius Is The.

This radius is dependent on the material. When designing sheet metal parts, understanding the minimum bend radius is crucial to ensuring the structural integrity and functionality of the final product. Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs. Your best bet when designing formed parts is to use the industry standard bend radius of 0.030”.

The Sheet Metal Bending Radius Is A Critical Value In Sheet Metal Drawing That Can Be Difficult To Determine During The Actual Processing.

The bend radius is the inside radius of a bent sheet metal part and has a direct impact on the part’s structural integrity, its ability to withstand stresses, and its final quality. How to implement the industry standard sheet metal bend radius.